Robot integrator

|

|

The importance of robotization in industry Automation of production in the world is becoming more and more common. Year after year we observe a growing interest in industrial robots by our customers. This is not surprising, as industrial robots have a very large impact on cost reduction by reducing cycle and changeover times. Their undoubted advantage is efficiency and repeatability. Our company specializes in manufacturing automation and robotization and performs customized projects. We offer programming for KUKA, Staubli, ABB and EPSON robots. |

Types of industrial robots

Nowadays on the market we can find many types of robots with different kinetic structures. These include:

|

Kinematic structure |

Description |

|

PUMA |

The most common type of robots in which all axes are rotatable (articulated). They are used for assembly tasks, welding, painting and palletizing of heavy workpieces. |

|

SCARA |

The robots having 3 rotary and one sliding axes. They are perfect for pick & place tasks of small parts. They have the advantage of higher main arm speed and relatively lower price than 6-axis robots. |

|

PORTAL |

Three linear servo assemblies forming a coordinate axis system. They are well used for tasks of dosing powders and liquids into various types of moulds. |

|

DELTA |

Three arms spaced 120 degrees apart allow for pick & place and packing tasks. The undoubted advantage of these robots is the placement of the drives outside the arms, which makes the kinematic properties much better than in the case of gantry and SCARA robots. Unfortunately, it does not perform the rotation function. |

With so many solutions available on the market, choosing the optimal robot kinematics for the task at hand is essential to maximizing production line efficiency.

Our qualified specialists ensure that the right robot is selected for the process requirements.

We work with many robot manufacturers that we use for our projects. We have licenses that allow us to program robots offline, which speeds up the set-up process and eliminates collisions.

Our realizations

|

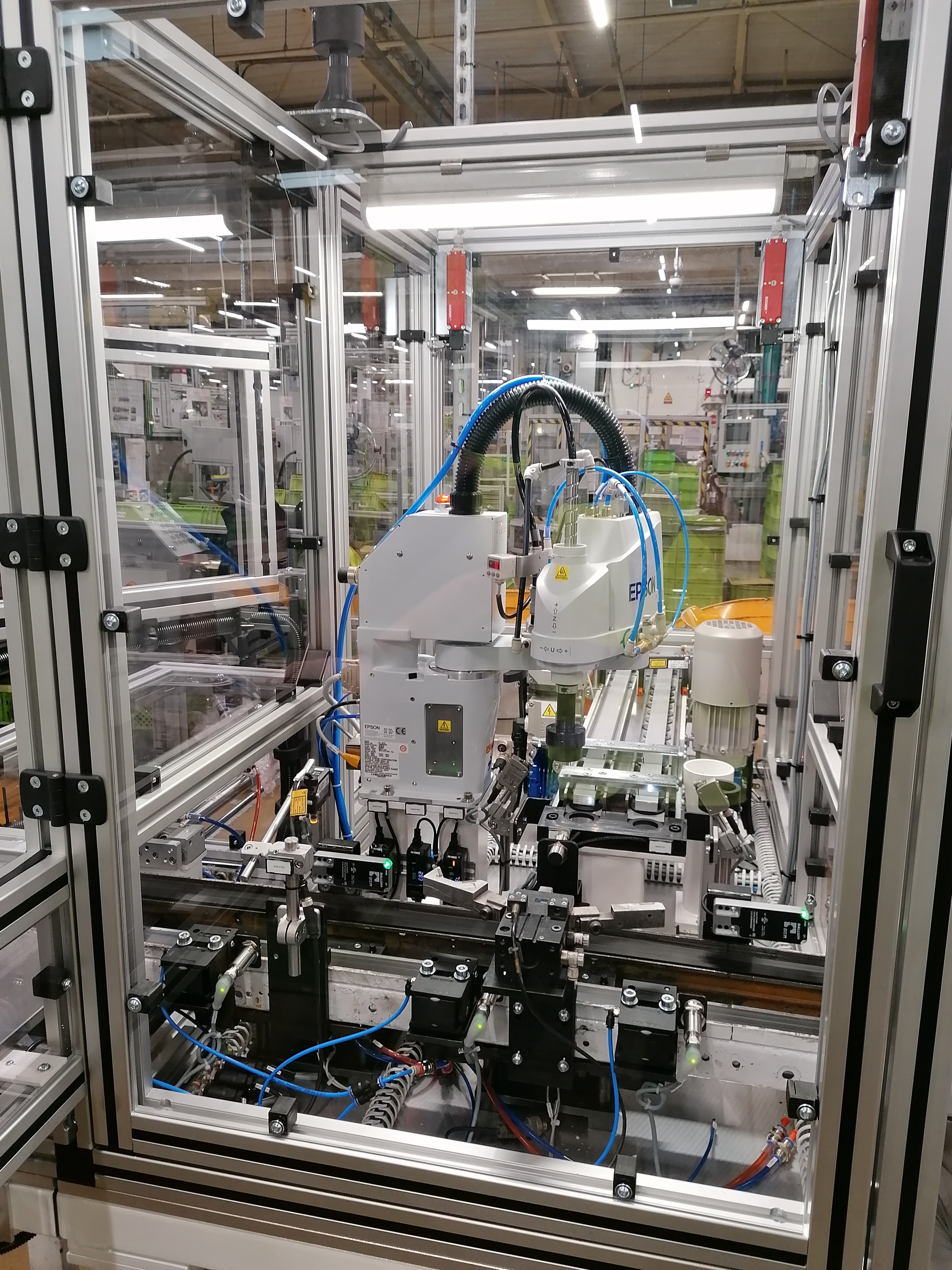

The gasket loading machine, consists of EPSON's SCARA kinematic structure robot that, depending on the selected reference checked by the RFID sensor, picks up a black or blue gasket and places it in the starter housing. If an error is registered, during assembly or housing inspection, the pallet with the workpiece is removed from the line to the chute of defective parts. The advantage of the device is the 3 second cycle time and immediate changeover. The robot is integrated into the PLC via PROFINET communication.

|

|

Teknomatik builds machines equipped with PORTAL robots. One of them is a machine dosing flux into foundry moulds. Cartesian robots are equipped with SIEMENS V90 drives and allow to reach any place in the form. Changeover time is limited to the selection of references from the operator panel. |

|

|

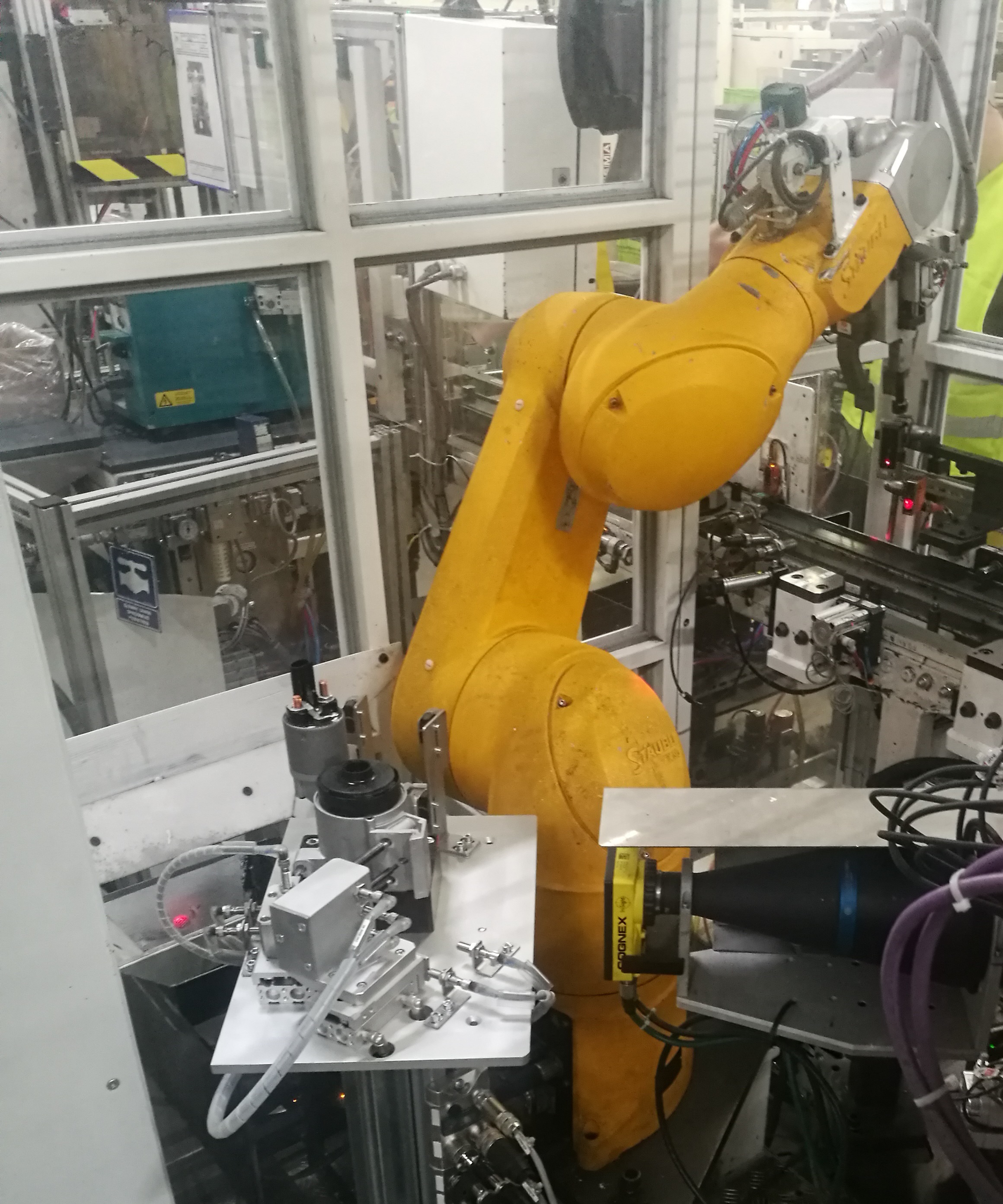

Another machine is used to control the presence of holes in the starters. It consists of a 6-axis STAUBLI robot that takes a workpiece from the line and places it in the inspection cell. After inspection, the robot deposits the workpiece on the line or transports it to the chute of defective parts. The robot communicates with the master PLC controller. |