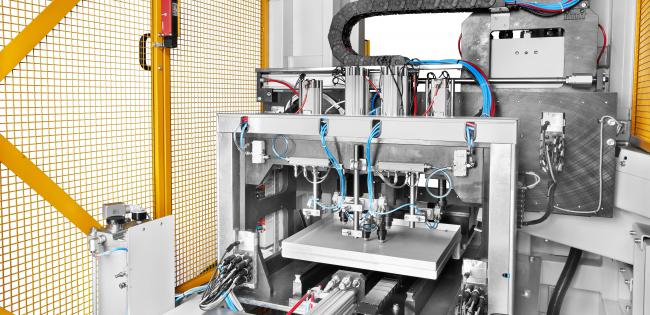

FRAME BENCH AUTOMATIC CONTROL STATION

An X-ray control station for steering knuckle casting. The station controls the quality and shape of the casting. Correctly casted detail is marked and unloaded into the transportation container.

|

Intended use of deviceThe ultrasound device, using ultrasound, is intended to examine and image the correct spheroidization of castings. In addition, a test of the correct casting shape is performed. Functional descriptionOnce the operator has inserted the workpieces into the seats and initialized the cycle, an automatic process consisting of the following operations is performed: - Travel of base with workpieces to the control area; - Application of oil through dosing nozzles to the points of contact between the probes and the workpiece surface; - Downward moving of the probes for inspection and measurement of the level of spheroidization of cast iron; - Return to the base position and marking the correct workpieces with pneumatic drilling machines; - Automatic depositing of correct castings into separate chambers of the transport container. |

Construction of device

| Workpiece base |

The base consists of two seats for workpieces (left and right), which reproduce the shape of workpieces, and built-in sensors check the correct placement of the workpiece;

|

| Measurement module |

Prior to measurement, the contact area between the probe and workpiece is wetted with oil so that there are no air bubbles between them; The degree of spheroidization is measured by 6 ultrasound probes at specific points on each casting;

|

| The principle to determine the correct spheroidization: |

The correct spheroidization depends on the magnesium content, i.e. for Mgü values above 0.027 a spheroidal cast iron is obtained: Mgü > 0.027 - spheroidal cast iron Ultrasound probes measure the velocities of ultrasound wave propagation in a casting; Velocities above 5550 m/s confirm that the cast iron is produced as spheroidal; |

| Discharge module |

After inspection, the correct parts are marked and then deposited in a container;

|

| Operator panel |

Siemens PLC, 7" HMI Panel;

|

| Structure |

Welded steel substructure of the machine;

|

| Level of safety assurance |

A number of technical safety measures were used, such as light curtains and safety locks. A measurement of the curtain run was made. A high safety category is provided.

|

Advantages for Customer / User

- Checking the correct performance of spheroidal iron castings

- Minimizing the risk of casting cracking during operation (e.g. brake callipers, car suspension arms, crankshafts);

- Relieving the operator by automatically unloading the correct castings.